Will Rusty Metal Ruin Your Bar Stools? How We Transform Raw Steel into Lasting Furniture

Rust: the nightmare haunting every metal bar stool owner. If you’ve ever wondered, “Can rusty steel still be used to make durable bar stools?” – the answer is a resounding yes, if processed correctly. At [Your Brand Name], we salvage and fortify steel through science-backed methods. Here’s how we combat corrosion at every stage.

Why Iron-Based Metals Rust (And Why It’s Not Game Over)

All ferrous metals (carbon steel, cast iron) oxidize when exposed to oxygen + moisture:

Myth: Rusty steel must be scrapped.

Reality: Surface rust is removable; deep pitting (>0.5mm) requires grading.

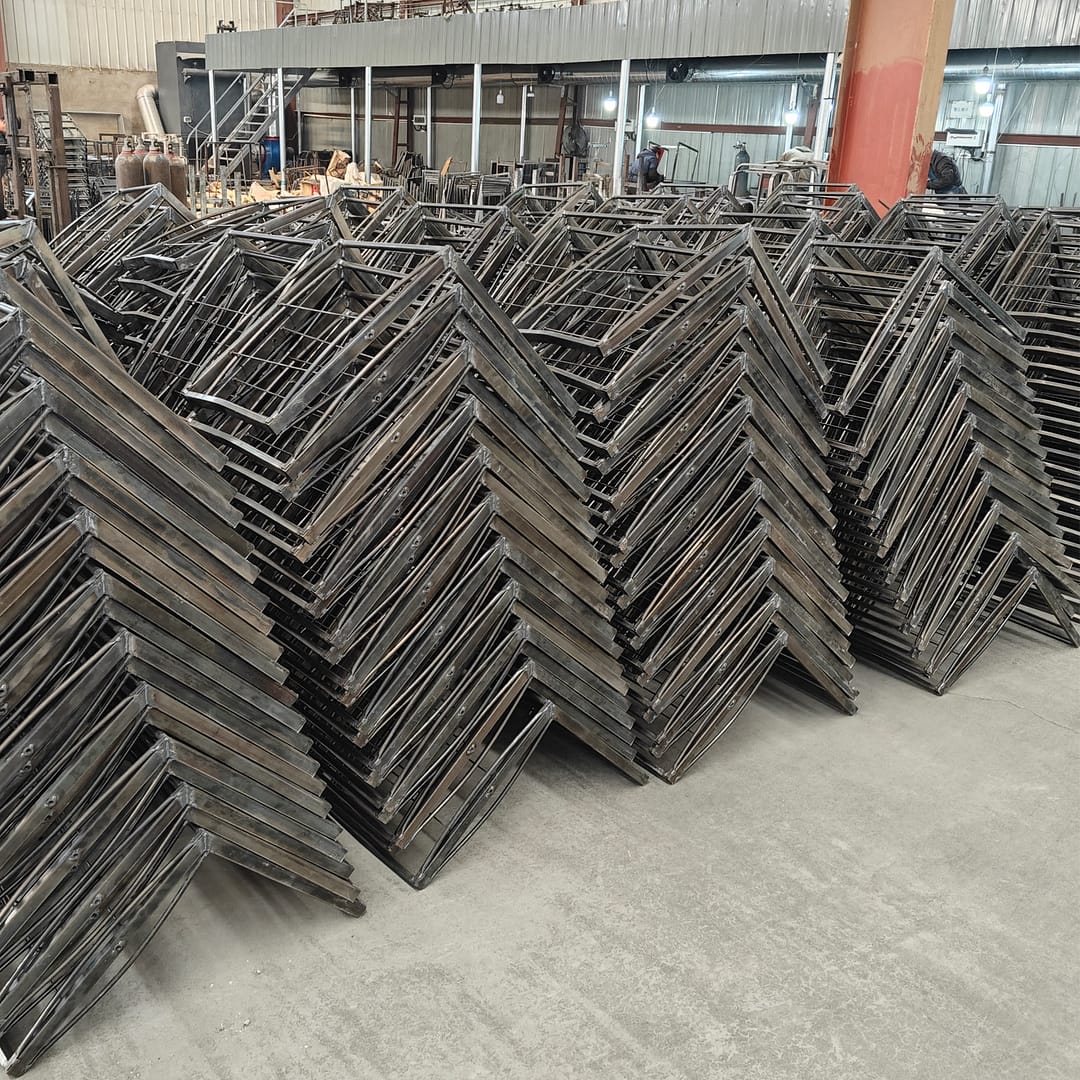

Stage 1: Rust Removal – Salvaging Raw Material

[Embed 45-sec Video: Our Multi-Stage Derusting Process]

We deploy a 5-step derusting system proven for bar stool production:

Testing: Derusted steel undergoes eddy current scans to verify integrity. Pitting under 0.3mm depth is acceptable per ASTM A123.

Stage 2: Powder Coating – The Ultimate Rust Shield

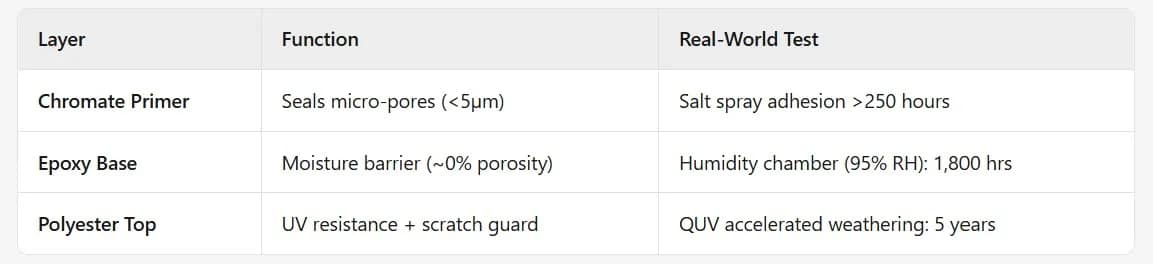

Powder coating isn’t paint – it’s a molecular armor system:

How It Works:

- Electrostatic Spray: Charged polymer particles (-30kV) cling to grounded steel.

- Infrared Curing: 200°C heat melts powder into cross-linked chains.

3 Rust-Blocking Mechanisms:

Critical Note: Cheap powder coating fails because:

❌ Skipping pre-treatment (phosphating)

❌ Low-cure powders (melt at <180°C → porous)

❌ Thin layers (<60µm total)

Our standard: 80–120µm thickness with dual-layer application.

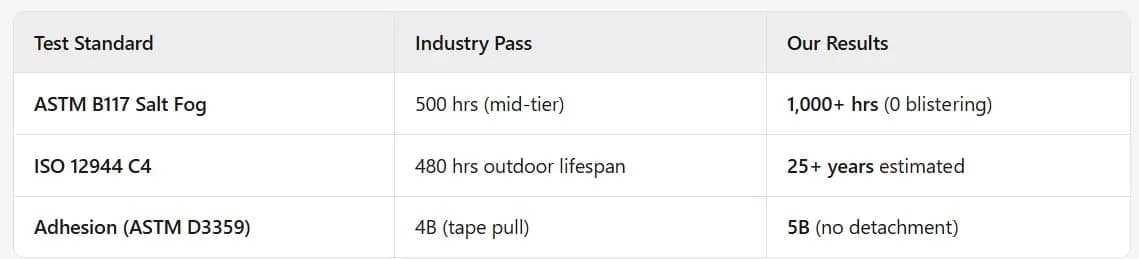

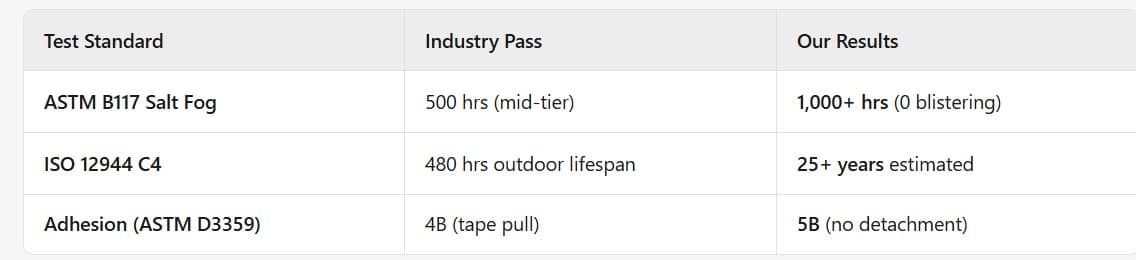

Rust Resistance Data: Industry Benchmarks vs. Ours

Extreme Environment Solutions: Beyond Basic Coating

For coastal bars/high-humidity venues, we add:

- Zinc-Rich Primers: Sacrificial zinc corrodes first (protecting steel)

- Seam Sealing: Silicone injection into welded joints (blocks moisture traps)

- Stainless Hardware: A2/A4 bolts prevent galvanic corrosion

(Case: Miami Beach restaurant reported zero stool corrosion after 4 years)

When Rust Indicates Poor Manufacturing

These flaws guarantee premature corrosion:

🛑 Weld Spatter: Unremoved blobs → coating voids.

🛑 Sharp Edges: Powder coating “crawls back” from corners → exposed metal.

🛑 Poor Drainage: Hollow tube ends trap condensation.

Our countermeasures:

- Post-weld grinding → smooth transitions

- End caps on all tubular sections

- Rounded edges (≥R1.5mm radius)

Maintaining Metal Bar Stools: Owner Checklist

Extend your stool’s lifespan with:

🔹 Weekly Wiping: pH-neutral cleaner (pH 6–8)

🔹 Avoid Chlorides: Bleach/sea spray accelerate rust

🔹 Inspect Scratches: Touch up with epoxy pens if coating chips

🔹 Prevent Standing Water: Use coasters in humid spaces

Quality Validation: How We Certify Rust Resistance

Every batch undergoes:

- Glow-Discharge Spectrometry: Measures Fe/Zn/Phosphates ratios pre-coat.

- Coating Thickness Gauges: 5-point checks per stool.

- Cyclic Corrosion Testing: 7-day salt spray → 4-day humidity → 120h UV repeat cycling.

2024 Data: Only 0.2% of stools showed edge rust after simulated 8-year exposure.

Conclusion: Rust is a Challenge, Not a Dealbreaker

Durable metal bar stools demand more than spraying over rust. Through rigorous derusting, multi-layer powder engineering, and design-intentional sealing, oxidized steel transforms into corrosion-resistant furniture.

At Bestyle Home, we don’t just coat metal – we re-engineer it against decay.

Explore Our Anti-Rust Tech: Derusting & Coating 360° Process.