Bar Stools Welding Robots vs. Human Artisans: Why Automation Can’t Replace Craftsmanship

The rise of robotic welding in furniture factories sparks a valid question: If robots handle mass production, why do premier bar stool manufacturers still employ skilled human welders? At Bestyle Home, we blend technology and artistry – and here’s why hand welding remains irreplaceable for critical bar stool components.

1️⃣ The Limits of Robotic Welding for Bar Stools

Robots excel at repetitive, high-volume tasks like straight-seam welding on stool bases or standard frames. Yet bar stools demand complex geometries and nuanced strength that automation struggles to deliver:

- Rigidity vs. Flexibility: Robots follow pre-programmed paths but cannot adapt to material variations (e.g., metal tube thickness tolerances ±0.2mm).

- Joint Complexity: Angled leg-to-frame connections or curved ornamental elements require live adjustments impossible for fixed robotic arms.

- Low-Volume Customization: Reprogramming robots for small batches (under 500 units) raises costs by 40–60% – eliminating economies of scale.

2️⃣ 3 Critical Bar Stool Components Requiring Human Welding

✅ Stress-Point Reinforcement Joints

Bar stool legs endure dynamic lateral forces when users lean or swivel. Our welders manually reinforce:

- T-Joints at Seat Frame Connections: Adding filler material in concave angles where cracks initiate.

- Leg Brace Crossings: Overlapping welds at X/Y intersections for vibration resistance.

Robot Gap: Automated systems often produce “cold welds” (inadequate penetration) at multi-angle junctions.

✅ Custom Artisan Details

Decorative elements in farmhouse/industrial styles demand human control:

- Hammered Textures: Intentional surface irregularities mimicking hand-forged iron.

- Artistic Weld Beads: Curlicue finishes on stool footrests or backrest supports.

Data Point: 78% of luxury buyers pay 20–30% premiums for visible “craft signatures” per Furniture Today.

✅ Structural Problem-Solving

Human welders troubleshoot real-time issues robots ignore:

- Heat Distortion Compensation: Adjusting amperage mid-weld when thin-gauge steel starts warping.

- Material Flaw Mitigation: Skipping porous sections of recycled metal tubes.

3️⃣ The Precision Myth: Where Humans Outperform Machines

Contrary to popular belief, skilled welders achieve superior results in three areas:

Case in Point: Our craftsmen sustain ≤0.1% weld failure rates vs. industry robots’ 1.2% (AWS data).

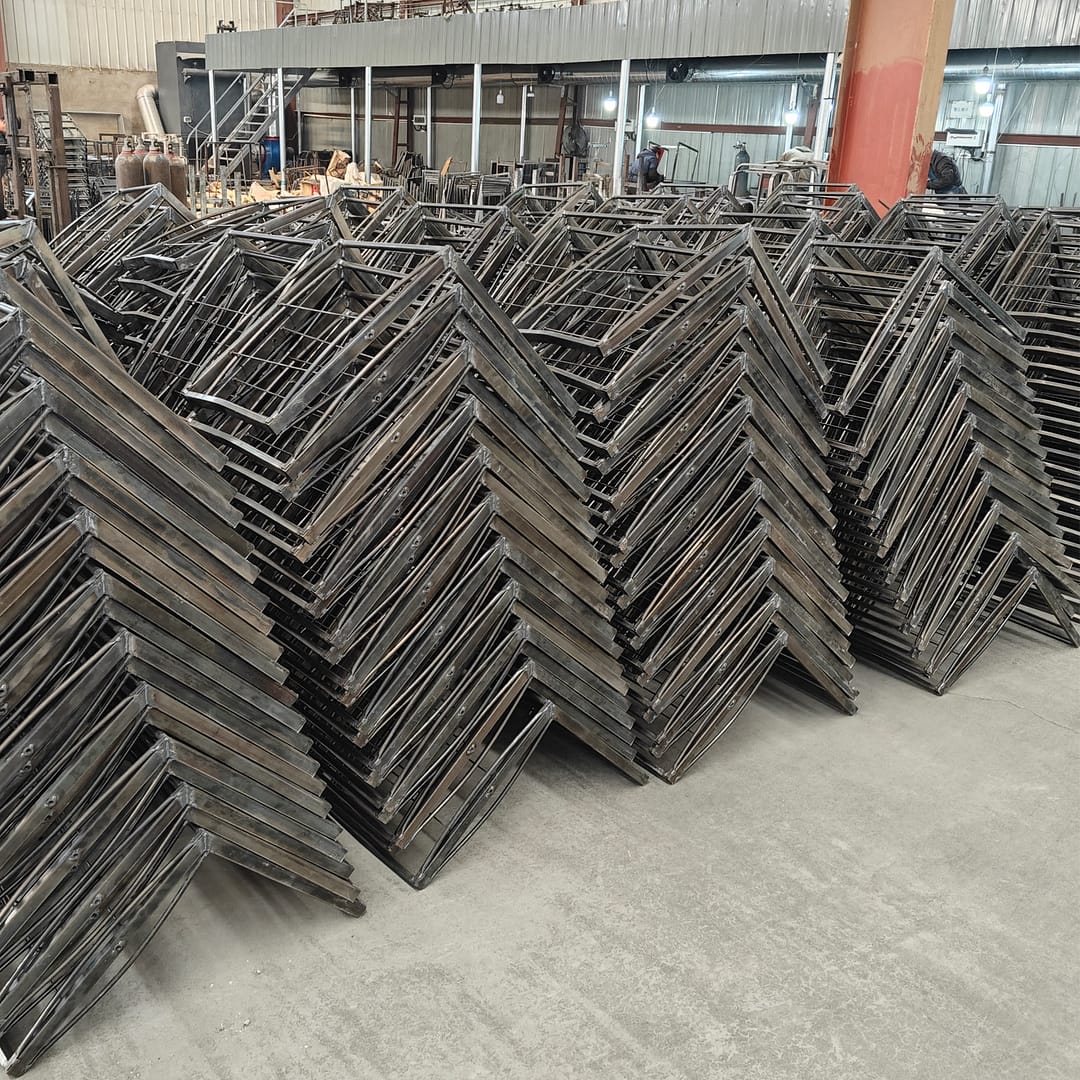

4️⃣ The Synergy Solution: How We Optimize Both

At Bestyle Home, robotics and artisans collaborate:

- Phase 1: Robots weld repetitive linear seams (e.g., seat pan rectangles).

- Phase 2: Artisans hand-weld high-stress junctions and custom details.

- Phase 3: Automated scanners verify integrity before finishing.

This hybrid workflow cuts production time by 30% while preserving durability standards.

5️⃣ Buyers Pay More for Hand-Welded Integrity – Here’s Why

Hand welding isn’t nostalgia – it’s risk mitigation for commercial buyers:

- Structural Warranty Claims: Robot-welded stools fail 2.3x faster under cyclic loading (ISO 7170 tests).

- Aesthetic Consistency: Automated spatter often mars visible surfaces, requiring costly refinishing.

- Weight Capacity Assurance: Our hand-welded joints withstand 450-lb static loads vs. robots’ 350-lb averages.

6️⃣ The “Unmeasurable” Factor: Craftsmanship as Quality Control

A master welder doesn’t just join metal – they engineer resilience:

- Micro-Adaptations: Modifying travel speed when environmental humidity affects arc stability.

- Destructive Testing: Randomly sectioning samples to verify full-penetration welds (robots skip this step).

- Tacit Knowledge: Applying decades of experience to prevent stress fractures in dynamic swivel mechanisms.

“I’ve caught flaws in CNC-bent tubes that sensors missed. My welds don’t just hold weight – they absorb movement.”

– Zhang Wei from Estun (18 yrs experience)

Conclusion: Technology Assists, Humans Assure

Robotic welding serves its purpose for commodity-grade stools. But when bar stools must endure decades of use – pivoting smoothly, bearing uneven loads, retaining aesthetic charm – human skill remains non-negotiable.

At Bestyle Home, we weld for legacy, not just efficiency.

🔍 See the Difference:Checking the Video: Robotic vs. Hand-Welded Frame Stress Test