From Steel Coils to Metal Bar Stools: The Hidden Transformation of Your Stool’s Frame

Have you ever wondered how raw steel becomes the sleek, sturdy frame of your favorite metal bar stool? At Bestyle Home, we unveil the industrial alchemy turning flat steel strips into precision tubing – and finally, into durable bar stools built to last decades. Discover why this process matters for quality and how we master it.

Stage 1: Steel Coils → Circular Tubes (The Foundation)

[Embed 60-sec video: Steel Coil Unfurling & Tube Forming]

All premium metal bar stools start as cold-rolled steel coils (1.0–2.0mm thickness). Here’s how transformation begins:

1️⃣ Uncoiling & Flattening: 5-ton coils unwind through de-scaling rollers, removing mill-scale impurities.

2️⃣ Edge Trimming: Laser-guided cutters trim edges to ±0.1mm precision for seamless seams.

3️⃣ Forming Roll Stages:

- Strip edges curl inward (➔ “C” shape)

- Squeezed into “O” shape with overlapping seams

- High-frequency welding at 1,100°C fuses seams

4️⃣ Cooling & Sizing: Newly formed tubes pass through water-cooled dies, achieving exact diameters (e.g., 25mm, 38mm).

🔍 Why This Matters:

Weld integrity here determines stool longevity. Poorly fused seams crack under stress. Our tubes pass 5.5 MPa hydrostatic pressure tests – double industry standards.

Stage 2: Circular Tubes → Shaped Tubes (Strength Engineering)

[Embed 45-sec video: Tube Squaring & Shape Stamping]

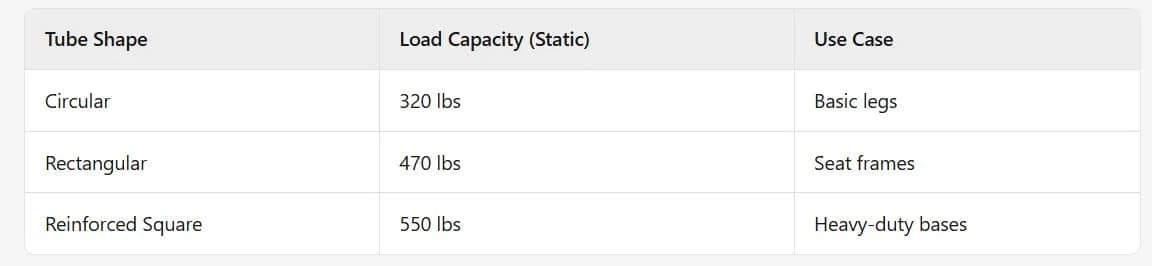

Metal bar stools demand rectangular, square, or oval tubes for:

- Higher rigidity-to-weight ratios

- Flatter surfaces for bolt-on components

- Sleeker visual profiles

We reshape circular tubes via rotary tube milling:

1️⃣ Heat Treatment: Tubes heated to 750°C (annealing) for malleability.

2️⃣ Roll Forming: Progressive dies gradually compress tubes into shapes:

- Round → Oval → Rectangular (for seat frames)

- Round → Square (for leg posts)

3️⃣ Seam Reinforcement: Additional welding along new corners prevents buckling.

📊 Strength Data:

Stage 3: Precision Tube Bending (Framing the Stool)

[Embed 50-sec video: CNC Mandrel Tube Bending]

Tubes become functional stool geometries via CNC mandrel bending:

- CNB-X7 Machines: Bend up to 120°/meter without crimping.

- Internal Mandrels: Prevent kinks during tight-radius bends.

- Accuracy: ±0.5° angle tolerance for perfect leg alignment.

Failure Example: Non-mandrel bends create “ripple walls” reducing load capacity by 40%.

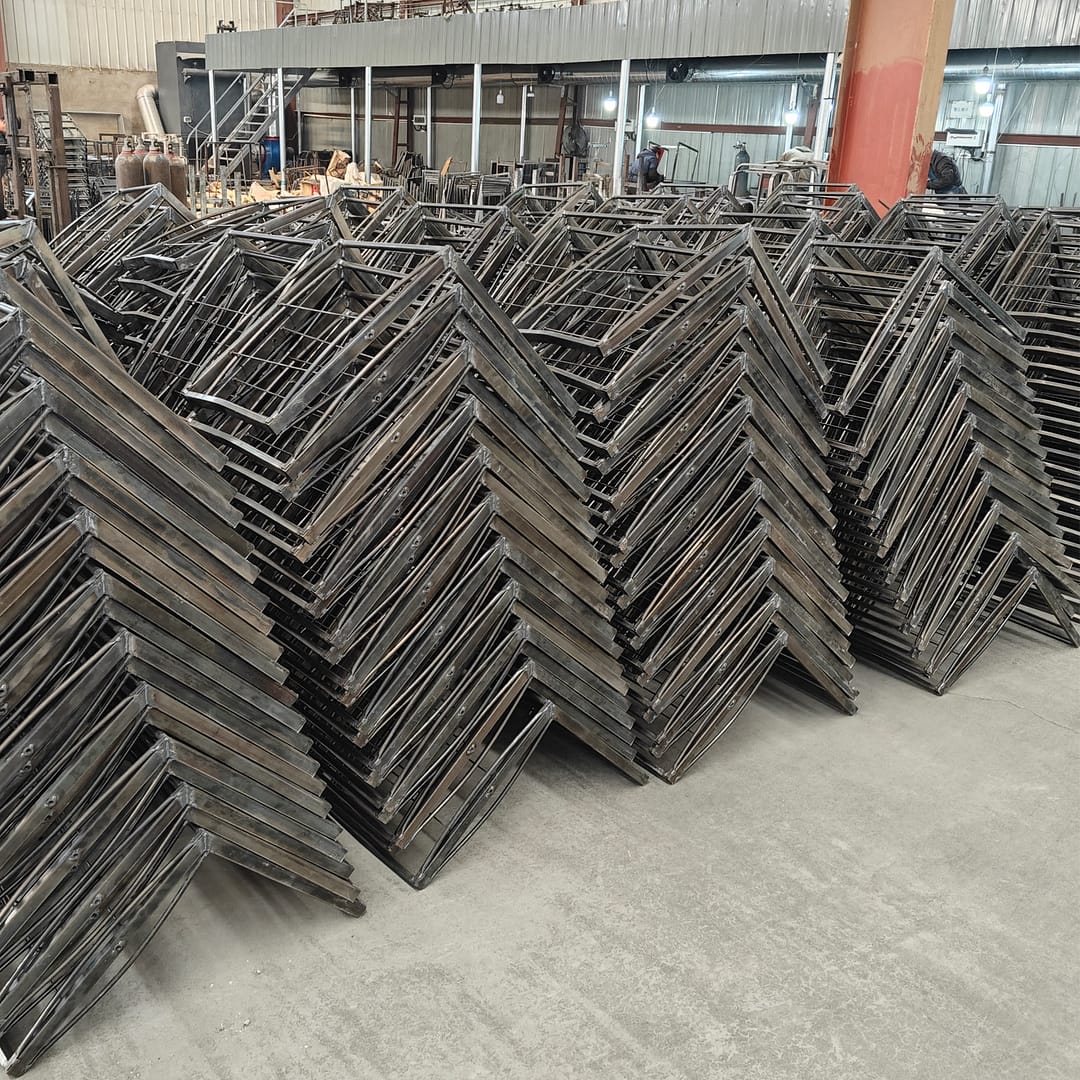

Stage 4: Assembly → Final Bar Stool

Your metal bar stool takes shape through:

1️⃣ Laser Cut Connectors: 3D-kissed joints ensure leg-to-frame stability.

2️⃣ Robotic Welding: Seam welds on straight sections (consistency).

3️⃣ Hand Welding: Stress points & custom joints (precision).

4️⃣ Powder Coating: Electrostatic spray + infrared curing for scratch resistance.

🛠️ Quality Spotlight: We use SAE 1008 Steel for tubing – lower carbon = smoother welds and tighter bends vs. brittle alternatives.

Why Steel Quality Dictates Stool Performance

Cheap metal bar stools often use non-remilled scrap steel, causing:

⚠️ Porosity holes in welds

⚠️ Uneven wall thickness (weak load points)

⚠️ Premature rusting from impurities

Our vertically controlled process ensures:

✅ Material Traceability: Every coil batch ID tracked.

✅ Chemical Composition Reports: <0.08% sulfur content (prevents rust).

✅ Post-Forming Normalization: Relieves internal stresses for impact resistance.

The Proof: Testing Real-World Durability

[Link to Full Video: Destructive Testing of Stool Frames]

We validate frames through:

- Cyclic Load Tests: 150,000+ sit-stand cycles (simulating 10 years of use).

- 40° Leg Splay Impacts: Verifying joint integrity when tipped.

- Salt Spray Chambers: 750+ hours resistance for coastal environments.

(2024 data: 0.3% structural failure rate over 50,000 shipped stools)

Conclusion: More Than Just Tubes – Engineered Art

Your metal bar stool’s journey from steel coil to finished frame combines advanced metallurgy, precision engineering, and rigorous validation. This hidden process determines whether a stool wobbles in months or stands strong for generations.

At Bestyle Home, we don’t just make stools – we reinvent steel’s potential.

📌 Go Deeper into the Process: Check Full Steel Tube Production Video.